The 'Twins' - James Cutter and Prothero Sloop

Twin Boat Build Contrasts Traditional and Modern Boatbuilding Methods and Materials

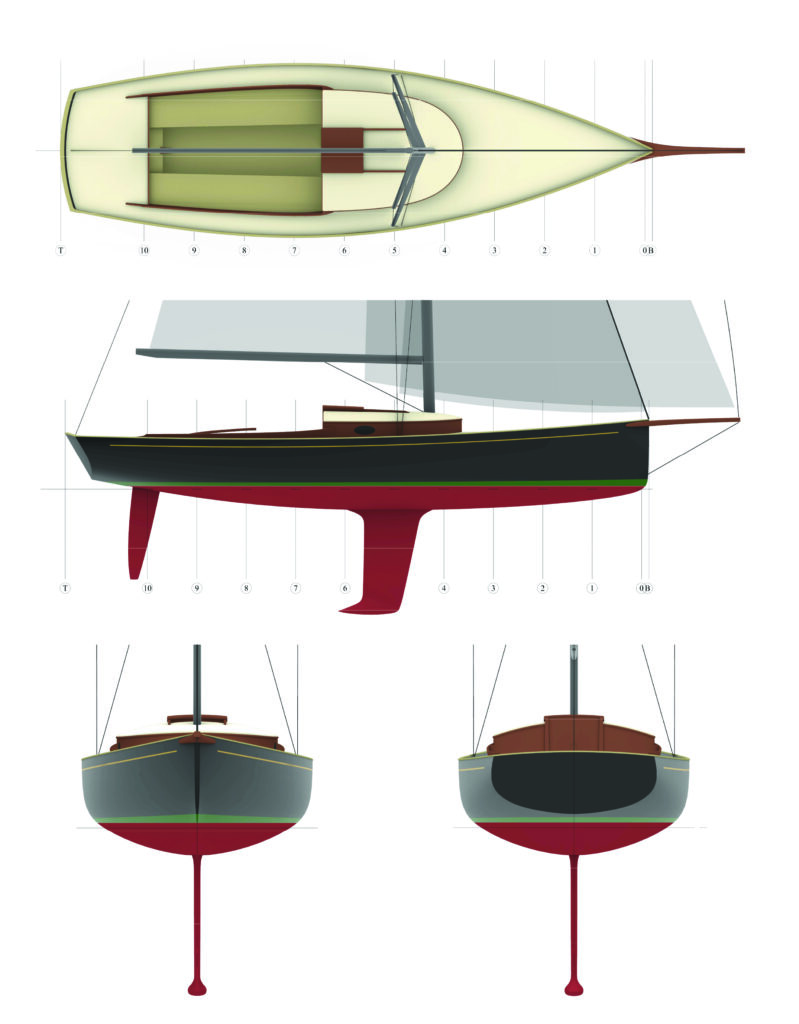

In January of 2025, the boatbuilding program began the construction of two 26’ sailboats built side-by-side. Though “twins” in size and general appearance, the James Cutter (pictured) will give students experience with traditional plank-on-frame construction. The Prothero Sloop (pictured), will give the same group of students experience with cold molding. The James Cutter was designed by Jim Franken of Port Townsend and the Prothero Sloop was designed by Will Sturdy at the Brooklin Boat Yard to support this unique learning experience.

What's similar about the builds?

Both boats are built out of wood and both hulls will be lofted and set up in similar styles. Each boat will be built upside down the decks of both hulls are built simultaneously—right alongside each project. Below the waterline, the hulls will be very distinct from one another, but above the sheer line they will have very similar cabin house and cockpit assemblies.

Rendering of the Prothero Sloop to be built with a composite hull through cold molding construction.

Rendering of the James Cutter to be built as a traditional plank-on-frame construction.

What's different about the builds?

The traditionally built James Cutter hull will consist of plank-on-frame construction. Essentially all the individual members of the hull will be held together by joinery and bronze fasteners.

The Prothero Sloop wood composite hull will use a much light-er construction technique called cold molding and will be built in the spirit of tradition style: a traditional looking topsides with a more modern fin keel/spade rudder under water, yielding a higher performance sailboat matched with a higher performance rig.

Building the builders

This dual project will challenge students to demonstrate competency in all skill areas and the qualities most valued by future employers. These include a commitment to full participation in every phase of the project, ranging from heavy lifiting and repetitive work to fine joinery, creative problem solving, and online research—doing whatever is necessary for the success of both the team and the project. Students will gain firsthand insight into what the trade involves. This experience offers valuable exposure to the properties of different materials, including solid wood, metals, bronze, G10, composites, and two different rigs—spruce on one and carbon on the other. This exposure is incredibly beneficial, as it mirrors what students will encounter in real-world work environments

Designing the Future: Coast-to-Coast Training

Brooklin Boat Yard (BBY), located in Brooklin, Maine, is a renowned wooden boatbuilding facility with a rich history of crafting traditional and custom vessels. Known for its craftsmanship and attention to detail, the yard specializes in designing and building both classic and modern wooden boats. In early 2024, Sean Koomen, Boatbuilding Program Director at the Northwest School of Wooden Boatbuilding, approached Brooklin Boat Yard to collaborate on the Twins Project, where they designed a fast, lightweight daysailer that combined modern performance features with the essence of a traditional pilot cutter.

This project also offered a unique learning opportunity for Oliver Lardner, a young, enthusiastic employee at Brooklin Boat Yard, where the Prothero Sloop was designed. Seeing his potential, Brooklin Boat Yard sponsored Oliver to attend the school and learn from instructors on this special project. Read more about Oliver at the Brooklin Boat Yard website by clicking here or on the image below.