KOREY RUBEN | 2014 | BOATBUILDING

Korey had always been interested in building things, but it didn’t come together as a career until he found the Boat School. In this video, he describes his journey from building cutting edge carbon fiber composites to applying his skills to major yacht renovations before returning to NWSWB as a boatbuilding instructor. “Projects that can make students problem solvers is probably the best you can do. If they understand they can dream it, they can build it.“

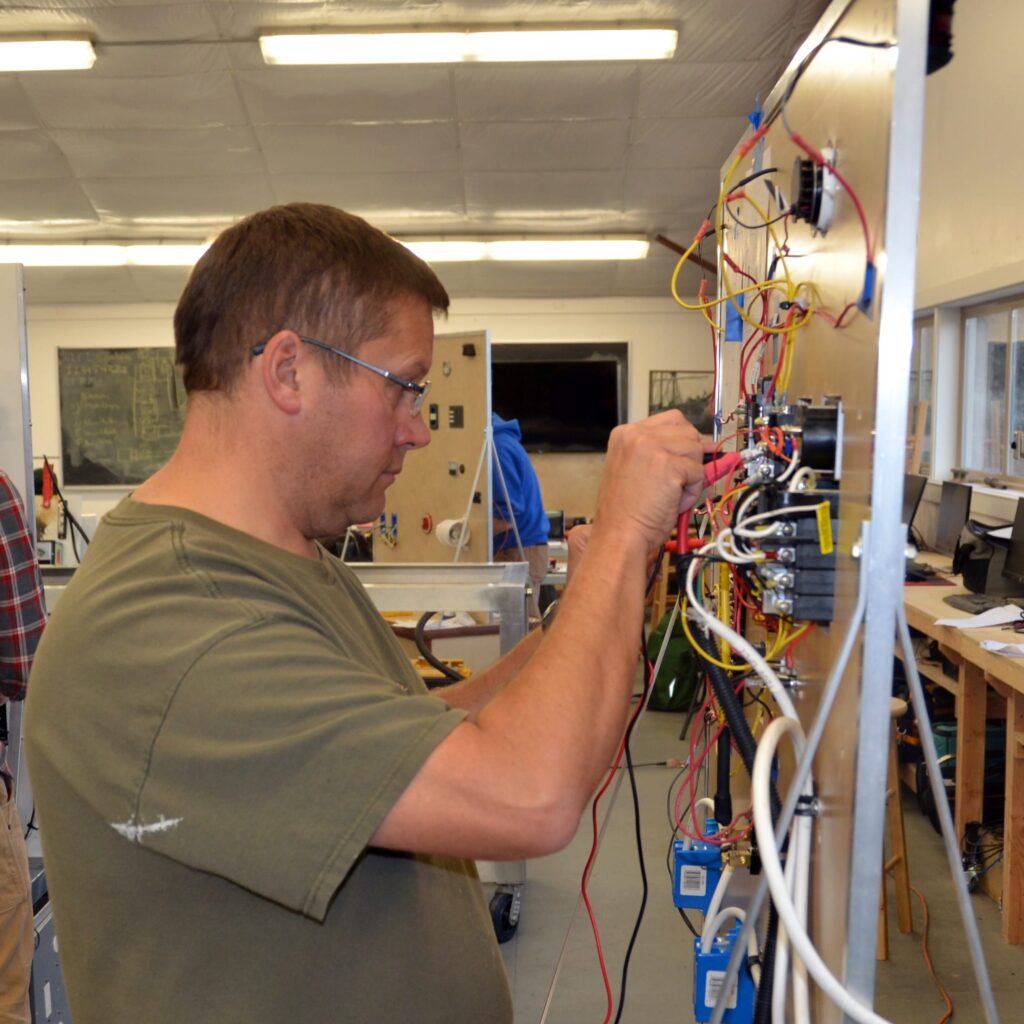

NED FLASH | 2021 | MARINE SYSTEMS

Boats have been in Ned’s life since he was a kid. Growing up he knew he wanted a career in the marine trades where he could do the work he loved and earn a dependable living. In this video Ned describes how he built a foundation of skill, experience, and self-confidence at the Northwest School of Wooden Boatbuilding to establish a sustainable livelihood. “The program was incredibly challenging, but as you learn the physical skills you also develop an understanding of why you’re doing it and your own way of working. That’s a whole new level. “

DEMIAN DETWEILER | 2019 & 2020 | WOODEN BOATBUILDING & MARINE SYSTEMS

Follow along this boat school student’s journey from the traditional boatbuilding program to marine systems to a career in the boat yard. Demien Detweiler shares his journey and reminds us all to remain passionately curious. “The Boat School changed the course of my life. The boatbuilding and then the marine systems program… and now to working in the yard. It has turned into a great career. I love it. It was the right decision for me to make.“

Zachary Haroth | 2017

Wooden Boatbuilding

Zachary credits his father with teaching him an early

appreciation for surfing, boats, and building things

— from tree forts to skateboards. After college, Zachary spent two

years in the Montana Conservation Corps in some of the wildest places in

the lower 48 and received an education award he used to attend NWSWB.

“Boat School taught me patience, helped me build my technical

woodworking skills, and brought my confidence to an all-time high,” says

Zachary. It also alerted him to a job opening for a Shipwright

Apprentice at the Chesapeake Bay Maritime Museum, where he has worked

since December 2017.

Jo Abeli | 2015

Wooden Boatbuilding

Jo Abeli, a history major, was drawn to the NWSWB because of the school’s restoration on the FELICITY ANN, the 23′ sloop that Ann Davison sailed solo across the Atlantic in 1953. After graduation, Jo worked as a boatbuilder at Haven Boatworks. Jo expanded her skill set by completing the one-week Marine Electrical and Marine Corrosion intensives. She currently works for the Port Townsend Shipwrights Coop.

ADAM SNIDER | 2017 & 2018 | WOODEN BOATBUILDING & MARINE SYSTEMS

Adam had a research career studying heart attacks and strokes but wanted to change to a career where he could work with his hands. After graduating from the Traditional Wooden Boatbuilding program, Adam enrolled into the 6-month Marine Systems Program. “I came to the school and found a chance to do something different, gratifying, and real.”

Misha Bogart | 2017 & 2019

Wooden Boatbuilding & Marine Systems

Misha graduated from the boatbuilding program and was was part of the inaugural Marine Systems program class. “Hands down, the most educational thing I’ve done in my life. It’s led to great things. It definitely made me competitive in the workforce.” Shortly after completing the Marine Systems program, Misha was hired by the State of Alaska to maintain their fleet of Fish and Wildlife law enforcement vessels and to captain one of their 85′ boats.

Justin Victoria | 2017

Wooden Boatbuilding

After graduation, Justin began working as a boatbuilder at First Light Boatworks, a yard established by the Pease Brothers in the 1930s to build, restore, and service wooden boats on the Mill Poind in Chatham’s Old Village, Cape Cod. “Being around super talented beings every day is the most rewarding feeling I’ve ever had,” says Justin. “I could never have experienced this without the support and knowledge the staff at NWSWB passed on to us.” From his first boatbuilding job, Justin spent a year working at Wooden Boatworks in Greenport, New York. Now he’s expanding his skills in interior house carpentry and furniture making at Rogue Built in Queens, New York.

GINNY WILSON | 2018 | WOODEN BOATBUILDING

Working in the trades always appealed to Ginny. With stints in welding, commercial fishing, and boat maintenance, she still longed to become a woodworker. After graduation, Ginny worked at the Port Townend Shipwright’s Coop helping to restore the historic WESTERN FLYER. She now runs her own business named Thorn Boatworks. “Happiness comes from solving problems. And boatbuilding is problem solving. The amount of confidence I built was transformational.”

Eric Schow | 2018

Wooden Boatbuilding

Eric graduated on a Friday and started working at Haven Boatworks the following Monday on the 105-year-old, 133-foot gaff-rigged schooner Adventuress. “I feel very lucky to have this opportunity,” says Eric. “There aren’t a lot of boats in the country or the world going through this level of restoration. Port Townsend is a mecca for boatbuilding. Going to Boat School was a great decision.”

Andy Blehm | 2016 & 2019

Wooden Boatbuilding & Marine Systems

“I took the wooden boatbuilding class at NWSWB as a break from software development. I wanted to get out from behind a desk and do something new. The boatbuilding was really fun and interesting, but I didn’t want to give up on 20 years of software experience. Then I heard about the Marine Systems program and I thought, “What if I combined this wooden boat stuff with marine electrical or hydraulics? That would be a pretty cool skill set. There’s lots of problem solving in Marine Systems and that appeals to me. “The way the program is designed, you go from the theoretical to doing it yourself in a controlled environment, so you really understand the procedure, to going onboard a boat where the bilge pump and the battery aren’t two feet apart, they’re 12 feet apart. The field work was incredibly valuable. In the classroom you’ve got your battery and your nice clean wire. Then you go onboard a boat, open the panel, and it’s spaghetti. You have a mess and you have to figure out what to do about it. That’s what it will be like on the job.” Andy is working as a marine technician for his own business, AB Marine Systems, in Port Townsend, Washington.

SETH EALY | 2016 | WOODEN BOATBUILDING

Seth was looking for a new career that was artistic and creative where he could work with his hands. Three months into his boatbuilding program he realized there was a science and an art to boatbuilding. “It was really rewarding and a great educational experience,” says Seth who was part of a team building a replica of a 1948 Whitehall from start to finish. The day of graduation, he got a call to join the team at Cape George Boatworks.

Julia Hechanova | 2016

Wooden Boatbuilding

Julia practically grew up at the Dolphin Swimming and Rowing Club in San Francisco, where her parents introduced her to traditional wooden boats like BAGGIANI, a 1948 Whitehall that became the model for a Whitehall the club commissioned from the school. After graduation, Julia returned to California to work as a boatbuilder in the Dolphin Club Boat Shop, helping restore and maintain the historic boats in their livery.

Josh Tolkan | 2017

Wooden Boatbuilding

Josh learned to paddle and sail at summer camp on Lake Michigan. He went on to start a sailing club while attending Carleton College, sail the collegiate racing circuit, and spend a SEA Semester (study abroad program) on the tall ship/research vessel SSV Corwith Cramer. Following Boat School he launched Many Waters Boatworks and Carpentry to serve recreational boaters in the Midwest and recently became Artisan in Development at the North House Folk School, where he teaches boatbuilding and woodworking classes and “gets to spend two years on the beautiful north shore of Lake Superior designing and building boats.”

David Klco |2016 | Boatbuilding

David Klco was a senior in high school when he was at a garage sale and picked up an old book that would change the course of his life. It was the 1941 classic Boatbuilding by Howard Chapelle. He brought the book home and spent hours studying the detailed plans for building wooden boats of every variety, from flat-bottom rowboats to ocean cruisers.

David grew up around boats on the Great Lakes of Michigan, but his experience was with fiberglass and aluminum boats. However, discovering Chapelle’s book, even all those years ago, was a career-changer. David had already been accepted to the engineering program at Michigan Tech, and he followed through with his plan to earn a degree – he even worked for two years as a software engineer at Garmin, a leading provider of navigation products for cars, planes, and boats. But David wasn’t interested in making a career of it. He was saving for boatbuilding school. In 2015, he was ready. He quit his job at Garmin and enrolled at the Northwest School of Wooden Boatbuilding.

“I came to the Boat with experience as a hobbyist woodworker,” he says. “I wasn’t an expert, by any means, but I was familiar and comfortable with a lot of the tools. But boatbuilding is considered by many to be the pinnacle of woodworking because nothing is square. Nothing is clear cut.

Following graduation from Boat School in 2016, David was chosen to serve as a Prothero Intern, a six-month paid position that lets one or two students spend additional time at the school honing their skills in an environment that offers increasingly more challenging work.

While working as an intern at the Boat School, David applied and accepted a position at Van Dam Custom Boats, a maker of meticulously crafted wooden boats, based in his home state of Michigan. “I take my work seriously,” he says, “but I believe we build boats because we love to. It’s fun and hard, and all that hard work culminating in something so graceful, beautiful, and practical is meaningful and worthwhile.”

“Becoming an expert boatbuilder is a lifetime thing,” Davis says. “I love that you can always learn to do something better.”

RILEY MCMATH | 2017 | BOATBUILDING

As a kid Riley wanted to go on adventures and boats were part of that. The scale of boat school projects made a big impression on him. He remembers sharpening tools the first week of school and his fingers were raw, but he knew it would be worth it because he was building the foundation of skills he’d be using for the rest of his life. After graduation he worked as the Boatshop Manager at the Northwest Maritime Center and is currently working as a shipwright at Haven Boatworks.

Zach Guenther | 2016

Boatbuilding

Zach discovered he loved woodworking when he answered a Craigslist ad for furniture restoration. “It was mostly sanding and putting a new finish on beat-up family heirlooms,” he says. “It taught me the basics, but I wanted to learn more.”

While researching woodworking schools, Zach saw a link for the Northwest School of Wooden Boatbuilding. “I didn’t have much experience with boats, except taking a skiff out for crabbing or fishing at the Jersey Shore, but boatbuilding seemed like an interesting way to learn more about woodworking.” A few months later, he was one of the new students in the class of 2017, starting his boatbuilding education with three months of drafting, lofting, and skiff construction.

Damian Hill | 2019

Marine Systems

“I grew up in a fishing town in Bristol Bay in Alaska, so I came in very much aware of the need for competent marine technicians to maintain these very high horsepower boats with thrusters, all these complex electrical systems, RSW to chill the catch down. When I found out there was a 6-month program to teach me everything I needed to get an entry-level job working on the boats, I signed up right away. The strength of the program is having experts right there, learning from people with deep knowledge. You can’t get that from a book. It’s hands on.

Amy Schaub | 2005 | Wooden Boatbuilding

Amy graduated from NWSWB in 2005 and then worked as a boatbuilder for three years before realizing she missed being on the water. She found work on a purse seiner in 2009 and worked her way up from deckhand to driving skiff to buying her won purse seiner in 2015.

Owning a commercial fishing boat was the last thing on Amy’s mind when she graduated college in 2000 with a degree in photography and limited job prospects in her chosen field. She’d never spent much time on boats, but growing up in Milwaukee she’d made friends with people who stories of seining for salmon, crewing on ore freighters, and sailing tall ships capture her imagination. While working to pay off her college loans, she signed up for an evening class in wooden boatbuilding and volunteered on the Denis Sullivan, the world’s only re-creation of a 19th century, three-masted Great Lakes schooner. The schooner’s builder, Rob Stevens, would become her boatbuilding mentor.

Three years later, Amy had earned her 100-ton Master Captain’s License and knew she wanted to attend boat school to learn to build and repair the kind of boats she’d been sailing.

“The skills I learned at Boat School – working with hand tools and power tools and seeing how construction all comes together – that was a huge asset for me,” says Amy.

When that job ended, Amy googled “boatbuilding without borders.” There is no such organization, but the internet search led to three months of volunteer work at the Tsunami Volunteer Center in Thailand, building small boats for fishermen who’d lost their boats in the December 2014 tsunami.

From there, she circled back to the Olympic Peninsula and found work at various boatyards over the next three years. Her skills and experience were growing, but she missed being out on the water.

Of the three options she considered – running a tender, crewing on a troller, or crewing on seiner – the seiner seemed like the best fit. Whatever the reason, it was prophetic choice, because crewing on the F/V St. Janet led to a deck boss position, which led to driving skiff on the F/V Norsel, which led to buying the F/V Norsel.

Because fishing is seasonal work, Amy was able to pair it with work as a marine tech for the U.S. Antarctic program. In the five years before she became skipper, she typically spent June to September fishing for a salmon in southeast Alaska; October to November fishing for salmon in the Puget Sound and Hood Canal, squid in California, or prawns in southeast Alaska; then December to March working as a marine tech on icebreakers in the waters off Antarctica.